Product Description

| Technical Parameters

|

| Material | 38CrMoAIA; SACM645; 42CrMo; SKD61 |

| Ntride Depth: | 0.5-0.8mm |

| Nitrided Hardness | HV900°~1000° |

| Nitrided Brittleness | above 2 stage |

| Surface Roughness | Ra0.4 |

| Hardess of surface chromium-plating after Nitriding | HV≥950HV |

| Chromium plating Depth | 0.05~0.10mm |

| Bimetallic Depth | 0.8~3.0mm |

| Bimetallic Hardness: | HRC50-65 |

| Certificate:

| ISO9001:2008 |

| Warranty | 12 months |

| Injection Screw Head/Nozzle/Tip |

| | 1. 38CrMoAIA(JIS SACM645)2. Cr12MOV(JIS SKD-11) 3. 4Cr5MoSiV1(JIS SKD-61)

4. 42Crmo(AISI 4140)

5. 40Cr 6. 9Cr18MOV |

| | 1: Heat Treatment2: High Frequency Treatment 3.Nitriding Treatment

4.Hard Chrome Plating Treatment

5.Bimetallic Coating Spraying Treatment

|

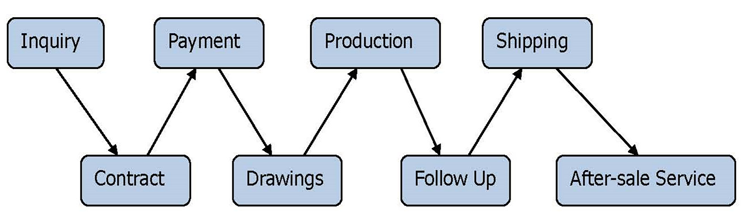

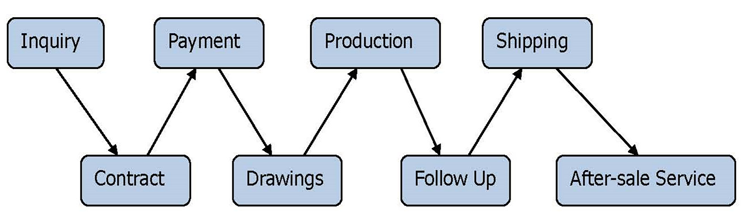

Technological Process:

Blanking→Rough Machining→Quenching & Tempering →Semi Finishing Machining→Finish Machining→Nitriding or Bimetallic Treatment→Detecting→Finished Product →Debugging After Treatment Products Show

Single Screw Barrel For Injection Machine ◆ Screw diameter: Ø15-Ø500 ◆ Mould clamping force: 25-32000KN

◆ Injection weight: 15-50000g

◆ Applicated machine:

Nessei, JSW, Fancu, Toyo, Toshiba, Mitsubishi, Kawaguchi, Meiki, Haitian, Haitai ,Engel, Battenfeld, Demag TMC etc.

◆Screw barrel parts: screw tip, seal ring, screw ring, nozzle, flange

Single Screw Barrel For

Extrusion Machine ◆ Screw diameter: Ø15-Ø500 L/D:15-45

◆ Application:

1.For Chemical fiber: PET, PAS, Non-woven fabric, Rope fiber

2.For plastic recycling and pelletizing

3.For carble extrusion: PVC, PE, PBT and rubber fluoride

4.For plastic product extrusion: Blow film, sheet, plate

◆ Screw structure and compression ratio can be designed according to different produtcs and raw material

Conical twin screw barrel For Extrusion Machine. ◆Model Type: 25/53,35/77,45/90,50/105,55/110,60/125,65/132,70/140, 75/150,80/156,92/188

◆Application:

PP,PE,ABS,PVC,Pelleting,Pipe,Profile,Sheet,WPC,PVC,WPC PE,Soft PVC, Sheet etc

◆Machine Brand:

CINCINNATI, BATTENFELD, KRUSSMASSEI,BAUSANO

Parallel twin screw barrel

Parallel twin screw barrel For Extrusion Machine ◆ Screw diameter:Ø35-Ø200, L/D:18-40

◆Machine Brand: CINCINNATI, BATTENFELD, KRUSSMASSEI,BAUSANO

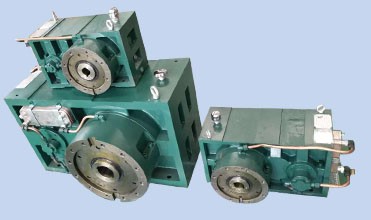

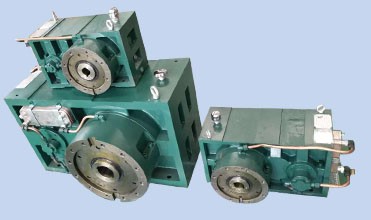

Gearbox For Extrusion Machine. ◆Model Type ZLYJ112, ZLYJ133, ZLYJ146,ZLYJ173, ZLYJ180, ZLYJ200, ZLYJ225, ZLYJ250 ZLYJ280, ZLYJ315, ZLYJ330. ZLYJ375, ZLYJ395, ZLYJ420, ZLYJ560, ZLYJ630

rubber screw barrel

rubber screw barrel 1. Cool feeding rubber screw and barrel: Speicification: Φ40-300mm L/D=8-20

2. Hot feeding rubber screw and barrel:

Speicification: Φ30-250mm L/D=4-8 3. Pin rubber screw and barrel:

Speicification: Φ60-250mm L/D=14-18

Our Advantage Bimetallic Screw: ① Strong abration resistance, good for the 30% glass fiber and reworked materials.

② Super hard alloy of high density, low porosity and high hardness.

③ Uniformity heating of power and low strength pressure.

④ With high corrosion resistance, high wear resistance and high temperature resistance properties.

Bimetallic Barrel: ① 2-5mm-thick alloy coat on the barrel inner wall

② Excellent corroion resistance, abrasion resistance and high working temperatre.

③ Useful service life is greatly improved

④ Able to process special plastic to enhance the abrasion life, such as engineering plastics, fluorine plastics, PPO, and tec. Our Service

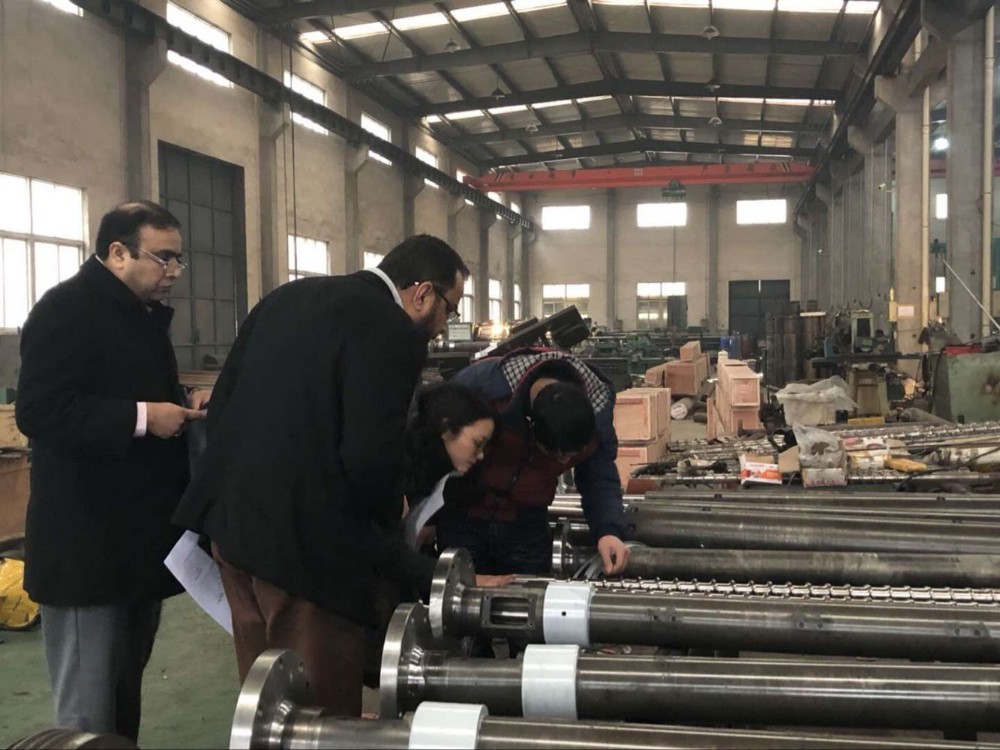

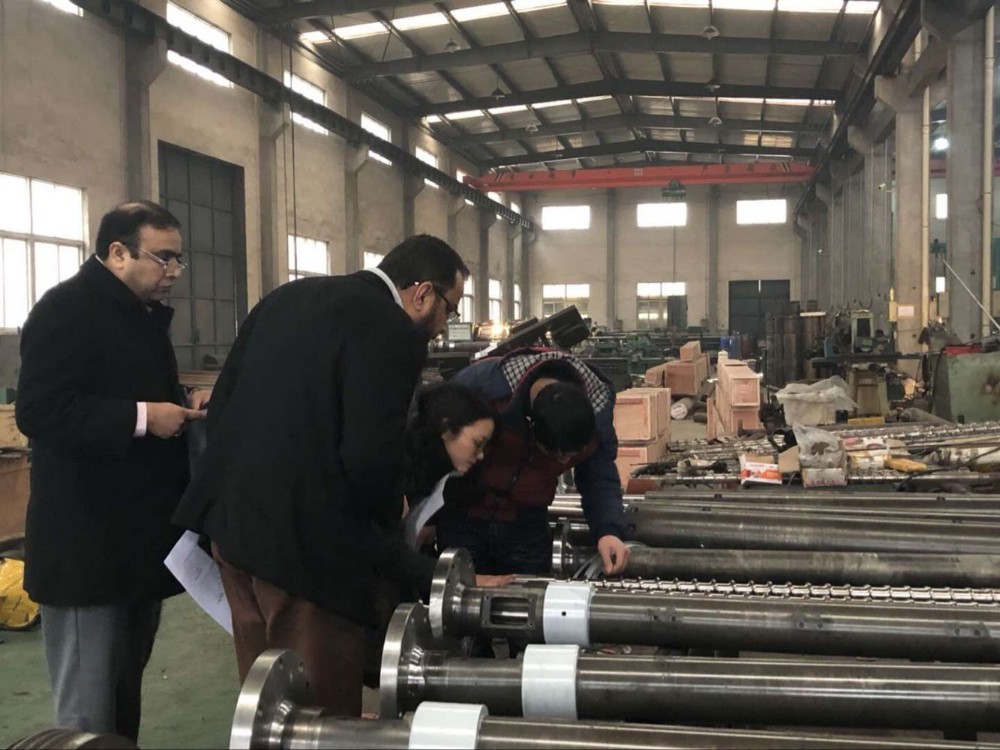

Oversea Measurement Service Exhibition Factory Visiting

Our Company

Zhongsu Screw Co.,Ltd located in zhoushan city, 1 hour driving distance from Ningbo port. 120 workers; 2200 ㎡ non-dust workshop; 20 years experience; 8 years' vendor of Haitian Injection; ISO certificated; That's how we keep good quality and competitive prices for global valued customers.Our main products cover: screw barrel and gearbox, heater band etc.

Workshop Workshop

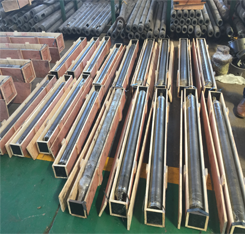

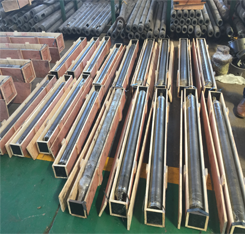

Ready to ship zone

Packing & Delivery Packing Details : Customized wooden cases (standard export packaging). Delivery Details : 25-30 days after order after 30% deposite and confirmation of drawings.

Step1: Finnal inspection Finnal inspection before shippment. Step2: Oil coating and film wrapping Waterpoorf oil and bubble fiml hlep to prevent demages during transportation. Step3: Finnal sealing Finnal sealing with tight strip and bound with Iron belts externally.

Our Certifications

FAQ Q: Are you trading company or manufacturer ? A: We are factory.

Q: How long is your delivery time? A: Generally it is 5 days if the goods are in stock and 25-30 days after the confirmation of the order.

Q: What is your terms of payment ? A: Payment<=1000USD, 100% in advance. Payment ≥1000USD, 30% T/T in advance ,70 %balance before shippment.

If you have another question, pls feel free to contact us as below:

Q: How about quality ensured? All of our production process stricktly followed ISO9001, our products are long durable with 12 months.

Contact us if you need more details on Screw Head. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Toshiba Injection Molding Machine、Barrel Nozzle. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Injection screw tip

Single Screw Barrel For Injection Machine ◆ Screw diameter: Ø15-Ø500 ◆ Mould clamping force: 25-32000KN

Single Screw Barrel For Injection Machine ◆ Screw diameter: Ø15-Ø500 ◆ Mould clamping force: 25-32000KN

Single Screw Barrel For Extrusion Machine ◆ Screw diameter: Ø15-Ø500 L/D:15-45

Single Screw Barrel For Extrusion Machine ◆ Screw diameter: Ø15-Ø500 L/D:15-45

Parallel twin screw barrel For Extrusion Machine ◆ Screw diameter:Ø35-Ø200, L/D:18-40

Parallel twin screw barrel For Extrusion Machine ◆ Screw diameter:Ø35-Ø200, L/D:18-40

rubber screw barrel 1. Cool feeding rubber screw and barrel: Speicification: Φ40-300mm L/D=8-20

rubber screw barrel 1. Cool feeding rubber screw and barrel: Speicification: Φ40-300mm L/D=8-20

Bimetallic Barrel: ① 2-5mm-thick alloy coat on the barrel inner wall

Bimetallic Barrel: ① 2-5mm-thick alloy coat on the barrel inner wall

Oversea Measurement Service Exhibition Factory Visiting

Oversea Measurement Service Exhibition Factory Visiting  Our Company

Our Company  Zhongsu Screw Co.,Ltd located in zhoushan city, 1 hour driving distance from Ningbo port. 120 workers; 2200 ㎡ non-dust workshop; 20 years experience; 8 years' vendor of Haitian Injection; ISO certificated; That's how we keep good quality and competitive prices for global valued customers.Our main products cover: screw barrel and gearbox, heater band etc.

Zhongsu Screw Co.,Ltd located in zhoushan city, 1 hour driving distance from Ningbo port. 120 workers; 2200 ㎡ non-dust workshop; 20 years experience; 8 years' vendor of Haitian Injection; ISO certificated; That's how we keep good quality and competitive prices for global valued customers.Our main products cover: screw barrel and gearbox, heater band etc.

Workshop Workshop

Workshop Workshop Packing & Delivery Packing Details : Customized wooden cases (standard export packaging). Delivery Details : 25-30 days after order after 30% deposite and confirmation of drawings.

Packing & Delivery Packing Details : Customized wooden cases (standard export packaging). Delivery Details : 25-30 days after order after 30% deposite and confirmation of drawings.

Step1: Finnal inspection Finnal inspection before shippment. Step2: Oil coating and film wrapping Waterpoorf oil and bubble fiml hlep to prevent demages during transportation. Step3: Finnal sealing Finnal sealing with tight strip and bound with Iron belts externally.

Step1: Finnal inspection Finnal inspection before shippment. Step2: Oil coating and film wrapping Waterpoorf oil and bubble fiml hlep to prevent demages during transportation. Step3: Finnal sealing Finnal sealing with tight strip and bound with Iron belts externally. FAQ Q: Are you trading company or manufacturer ? A: We are factory.

FAQ Q: Are you trading company or manufacturer ? A: We are factory. Contact us if you need more details on Screw Head. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Toshiba Injection Molding Machine、Barrel Nozzle. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Screw Head. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Toshiba Injection Molding Machine、Barrel Nozzle. If these products fail to match your need, please contact us and we would like to provide relevant information.