Find Two Stage Compounding Extruder Line, Extrusion Machine, High Quality Two-Stage Compounding Extruder Line on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Unit Price: | 32000~45000 |

|---|---|

| Payment Type: | T/T,L/C,D/A |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: 65-150-M

65/150 double-stage pelletizing extruder for PVC cable granules

double-stage extruder

Characteristic of two-stage extruder:

The KTE-SE series two-stage extruder consisted of two stage components. The first stage is SHJ co-rotating twin-screw extruder, the second stage is SJ Single Screw Extruder. This machine first of all to realize material better compounding and shearing by twin-screw, then the single screw fulfills the task of extruding and granulating.

The scientific and advanced structure can avoid material decomposition phenomena due to overheating. To combines the advantage of twin-screw and single screw together and complementation, likewise, propitious to every craft distribution and optimize so that making higher efficient and production capacity.

The two-stage extruder best suits for producing PVC, POM, XLPE thermo-sensitive material etc.

Main technical data:

Configuration:

1. Double stage extruder:

First stage: KTE-65 Twin screw extruder (Screw diameter: 62.4mm)

Section stage: SE-150 Single screw extruder (screw diameter: 150mm)

2. screw

1) Screw design: modular structure

2) The screw core shaft is made of 40CrNiMoA, and the screw thread components connect with the core shaft in an involute curve, which features high intensity, large bearing load, and easy to disassembly and assembly.

3) The screw components are made of high quality high-speed tool steel W6Mo5Cr4V2, that receives heat treatment with vacuum hardening at high temperature.

4) Whole hardness: HRC58-62

3. Air-cooling die face pelletizing systems

1)S.S. Thermal fan hood and die face thermal cutting pelletizer

2)Primary cyclone separator

3)Secondary Cyclone Separator

4)Vibrating sieve

5)Product silo, S.S made

Final product: PVC cable granules

>Electric control system:It is the core of the extruder ,because all the actions are controlled by it .so it must be with high quality and steady

>Workshop:

>Exhibition of Kerke:

2014 in Qingdao

2014 in Turkey

2015 Chinaplas in Guangzhou

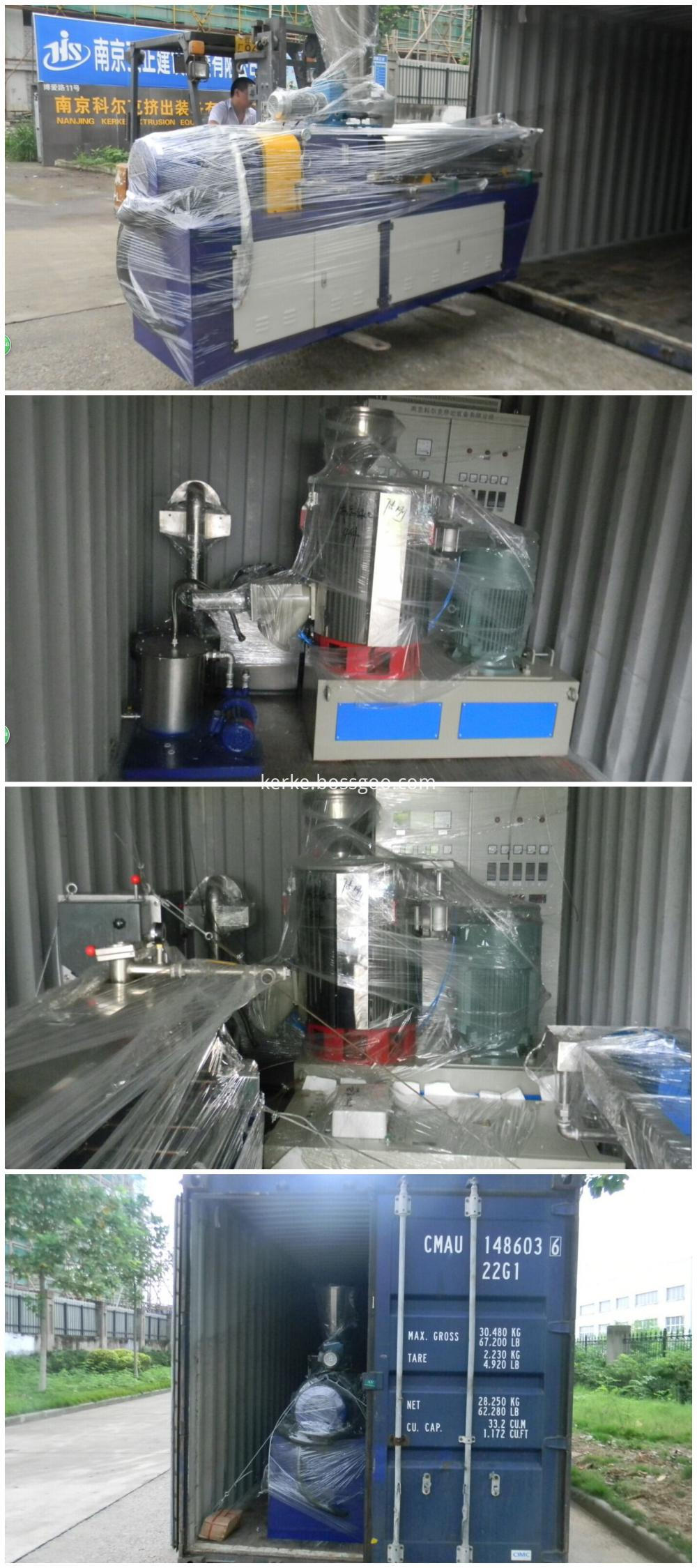

Packing and shipping:

Certifiate:

Product Categories : Two Stage Compounding Extruder Line