Find Air-Cooling Hot Cutting For Filler MC, Anti-Flame Masterbatch Twin Screw Pelletizer, Eva Carbon Black Twin Screw Granulator on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Unit Price: | 25000~35000 USD |

|---|---|

| Payment Type: | T/T,L/C,Western Union |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 40 Days |

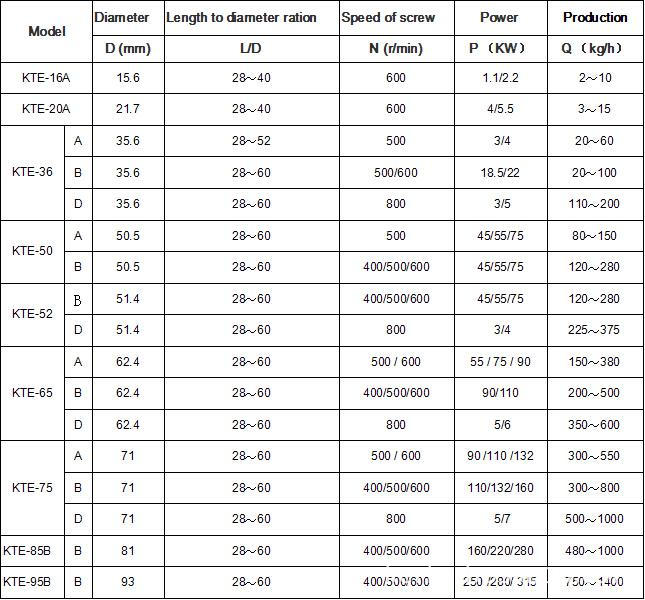

Model No.: KTE-36

Air-cooling die face pelletizing mainly used in materials whose moisture can easily result in product poor quality. Since

the material has no contact with water in the whole granulation process, so eliminating the dehydration part, to avoid

the second pollution of cooling water. The die face hot-cutting material particles look round, full and beautiful.

Application:

1. Enhanced modification: PE, EVA, etc. with calcium sulfate, talc, titanium dioxide, carbon black;

2. Biodegradable Masterbatch: PE, PS etc. with starch, additives, etc.;

3. Flame retardant masterbatch: PE, EVA, etc. with antimony trioxide, magnesium hydroxide, aluminum hydroxide.

>> Exhibition:

In those two years, we are participate in kinds of International Plastic extruder exhibition actively, such as in Turkey,

Vietnam, India etc. and received a huge succefully:

>> Customer thanks:

Since the foundation of our company, we always do everything to satisfy our customers' satisfaction and solve the problem actively, then received customer's high appreciation, It really our treasure! Wish we also can service you in the near future:

Nanjing Kerke is specialized in Modular structure Co-rotating parallel twin screw extrusion`s design and

manufacture, and manufacture extrusion equipment`s core components. Also Nanjing Kerke works on the

product development, manufacturing until to the Turnkey project in the related technology and engineering application!

Within current situation that domestic twin screw extruder and polymer products` manufacturing technology

behinds the international advanced level, Nanjing Kerke takes the lead in fully uses the modern CNC machining

centers, which has realized the leap upgrade in twin screw extruder`s manufacturing technology!At the same time,

Nanjing Kerke takes full advantage of domestic technical resources, and continues to manufacture more

cost-effective advantage extrusion equipment!

The purpose of Kerke: market is the direction and the quality is the life!

--KTE series Co-rotating parallel twin screw extruder for filler & color masterbatch, polymer blending, Fiber

reinforcement,etc.

--KTE/SE series Two Stage Compounding Extruder for PVC cable,black masterbatch,etc.

-- SE series Single screw recycling extruder for film recycled etc.

-- Extruder Screw and Barrel, etc wear parts.

-- Extruder Auxiliary machines.

Sales service:

>Recommending engineering conditions required for installation of the machine & equipment

>Communicating in time the manufacturing progress of the machine with user

>Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

>Providing on-the-spot technical assistance in installation, commission and training

>Filling in detail customer`s information

>Providing long-term maintenance service and Spare Parts

>Giving technical support to customer for developing new product

>Providing free maintenance for a year

Product Categories : Air-Cooling Hot Cutting Pelletizing System