Find Single Screw Extruder, Extruder Screws, Extruder Screw Barrel on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Unit Price: | 20~200 USD |

|---|---|

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Min. Order: | 10 Piece/Pieces |

| Delivery Time: | 30 Days |

Model No.: KTE-J

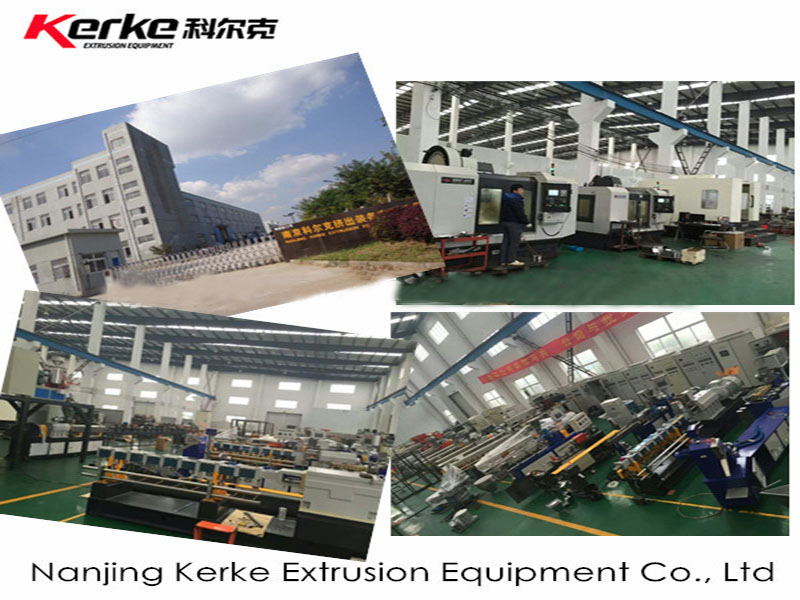

Nanjing Kerke Extrusion Equipment Co., Ltd is a comprehensive manufacturing and trading company in China. our company is a professional manufacturer of high quality pelletizing extruders for coloring /dyeing and masterbatch production, as well as plastic modification and compounding,plastic recycling. Innovative machines are built as per the concept of durability, high efficiency and economical power consumption. We carry out a strict quality management system in accordance with CE requirements. There are over 100 styles of extruder and extruder Spare Parts and we also can customize for customers' various requirement for extruder spare parts. Our annual production capacity is 200 sets plastic extruder in domestic country! And we also have OEM ability in pelletizing plastic extruder industry in consistence with specific requirement from both national and international customers. Moreover, we are pleased to introduce our company as one of the leading exporters of parallel twin screw extruder in China.

Description:

Parallel co-rotating twin screw extruders have excellent mixing performance,good self cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material systems,and are extensively used in fields of polymer processing ,foodstuff processing and chemical products, especially for various high molecular materials.

In most cases ,parallel co-rotating twin screw extruders are used as mixing equipments .ln processing high molecular materials,the modification process and master batch preparation of polyolefin materials and engineering plastics require sufficient and intensive mixing,which differs depending on material systems,Excellent equipment performance,reasonable mixing process, advanced combination technique and rich processing experience are the key factors determining the success and efficiency of mixing.

plastic auxiliary equipment

Twin screw extruder are modular structure design, wearing parts can be changed according to demands and requirements.

We produce and supply various kinds of replacement parts, such as screw elements, shaft, barrel, heater, feeder, side feeder, pelletizer, gearbox, gear, etc..

Material:

Screw elements: W6Mo5Cr4V2(high speed tool steel), 38CrMoAlA

barrel: 45# steel, bi-metal alloy inside liner

shaft: 40CrNiMo

heater: copper-casting, aluminium-casting

gearbox: inported bearings

All kinds of plastic auxiliary equipment supplying timely!

·

· Our Service

Sales service:

Recommending engineering conditions required for installation of the machine & equipment

Communicating in time the manufacturing progress of the machine with user

Providing assistance in technical conditions, screw combination and barrel disposition needed for product

After-sales service:

Providing on-the-spot technical assistance in installation, commission and training

Filling in detail customer`s information

Providing long-term maintenance service and spare parts

Giving technical support to customer for developing new product

Providing free maintenance for a year.

IF you are interested in our products, please feel free to contact me. :)

Contact us if you need more details on Twin Screw Extruder Barrel. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Recycling Pelletizing Extruder Barrel、Extruder Screw and Barrel. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Extruder Screw and Barrel