Find Strand Pelletizing Line For Fillers, Plastic Pelletizer, Plastic Pelletizing Machine on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Unit Price: | 20000~25000 USD |

|---|---|

| Payment Type: | T/T,L/C,D/A,D/P |

| Incoterm: | FOB |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 30 Days |

Model No.: KTE-52B-M

masterbatch double screw pelletizer

Description:

We are the manufactur of plastic pellet production line. Our products are widely used in producing variety of plastic pellet like PP PE PET ABS PVC etc;

They can widely used in industrial machinery ,construction material plastic machinery.

and we also have the machinery for small industries -- twin-screw mini plastic extruder. This type is suit for testing material or small factory.

All parts of the production line- twin-screw extruder

1.twin screw extruder

2. dryer

3.pelletizer

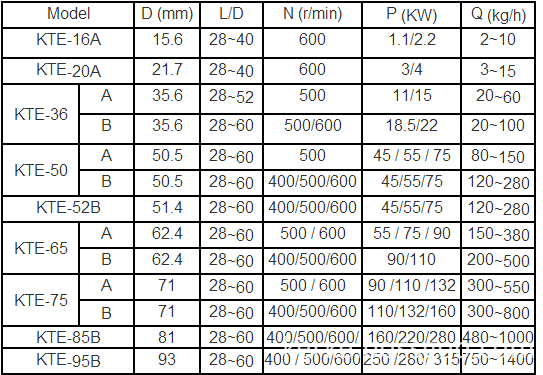

Main technical standards:

This is a parallel co-rotation twin-screw extruder

Because of its numerous advantages

>>This structure can afford a high speed to guarantee highly efficiency

>>Easy maintenance

>>Its self-cleaning can improve products quality and easy to clean.

>>building blocks barrel and screw can afford your variety requirements

All of our products are with high quality because we can`t bear even a tiny dissatisfied detail

>Screw and barrel : Screw: W6Mo5Cr4V2 high speed tool steel

barrel: 45# steel barrel body, inside line is made of bi-metal alloy.

shaft: 40CrNiMo

building blocks barrel and screw can adjust different materials

By means of the replaceable screw barrel sections, the processing sections is devoted into individual zones. The barrels are heated electrically. In addition, the barrels are provided with longitudinal bores for cooling with water. Uniform temperature distribution, namely on the circumference of the eight-shaped barrel bore, is achieved by a reverse force-flow temperature control circuit. Connections of pipes for temperature control are in groove-tongue design to balance alternating thermal stress and avoid leakage.

The screw barrels are made of nitrided steel. In order to increase the service life of the screw barrels, these are provided with wear resistant inserts.

>Electric control system:It is the core of the extruder ,because all the actions are controlled by it .so it must be with high quality and steady

>Workshop:

>Exhibition of Kerke:

2014 in Qingdao

2015 Chinaplas in Guangzhou

2015 in qindao exhibition

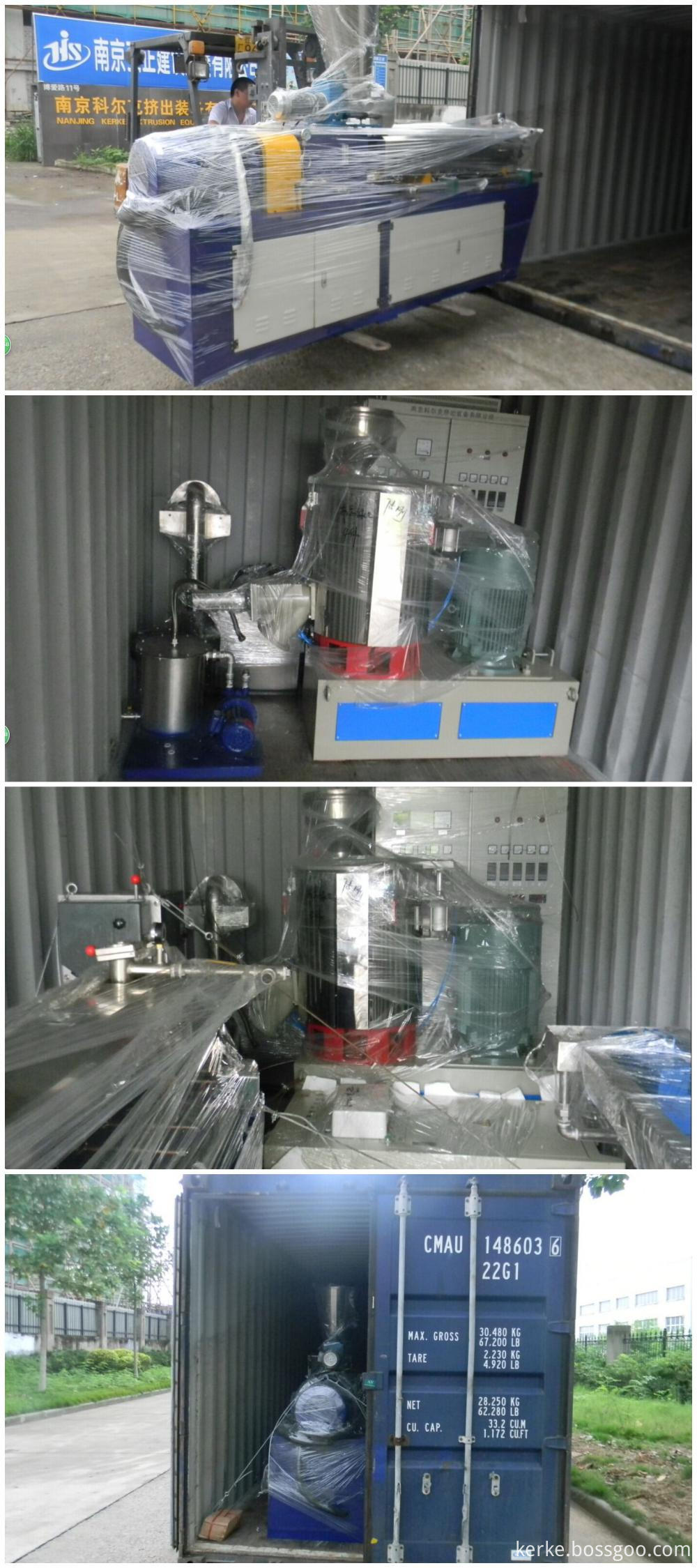

Packing and shipping:

Certifiate:

Product Categories : Strand Pelletizing Line for Fillers